Açıklamalar

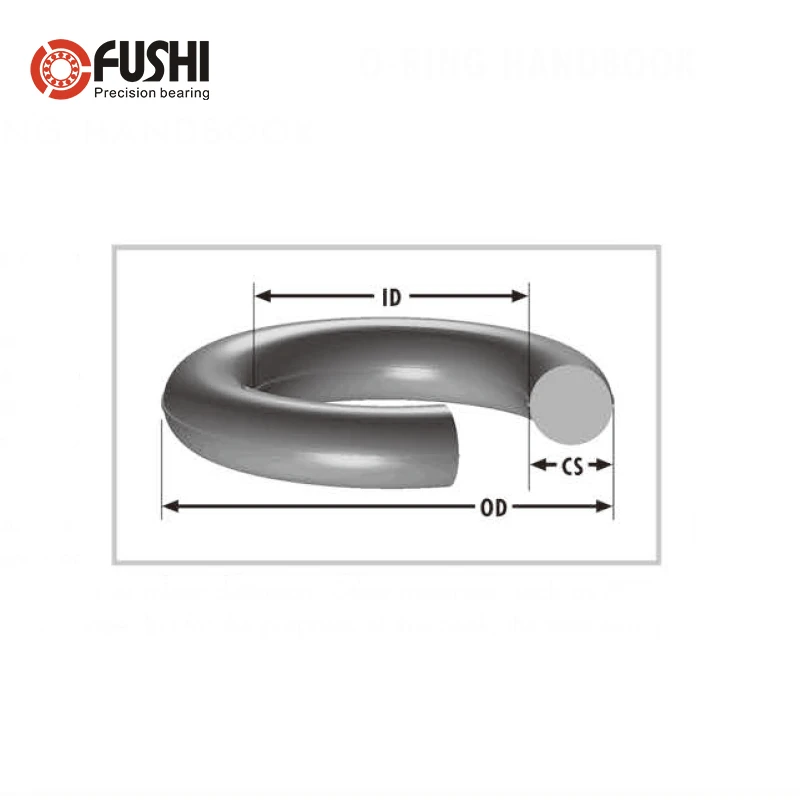

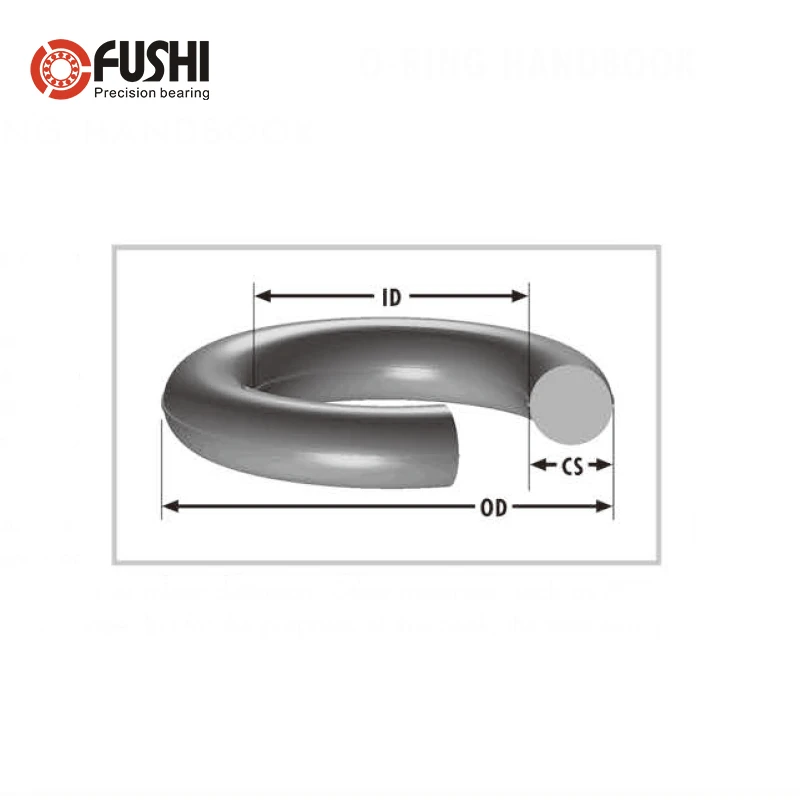

O-ring Sealing Rules O-rings are bi-directional seals, round in form and cross part. O-rings are typically made of an elastomeric materials, howevercould also bemade fromdifferentsuppliesequivalent to PTFE or metallic. An O-ring seals by way of the deformation of the seal materials by set up and media strain to shut off the hole between mating parts. Increased system pressures can trigger deformation by way of the hole, generally known as extrusion, leading to seal failure. Selecting a tougher seal materials or putting in back-up rings to assist the O-ring might alleviate this downside. Technique of operation O-Rings are double-acting sealingelements. The inital squeeze,which acts in aradialora xial pathrelying on the set up, provides the O-Ring its preliminary sealing functionality.These forces are superimposed by the system strain to create the overall sealing power which will increasebecause the systeme strainwill increase (Determine 2). Underneathstrain, the O-Ring behaves in asimilar option to a fluid with excessivefloorrigidity. The strain is transmitted uniformly to all instructions. EPDM (Ethylene-Propylene-Diene Monomer O-Ring): EPDM O-ring in auto elements, hygiene provides, medical tools, marine tools, petroleum tools, telecommunications tools, instrumentation, equipment and different industrial fields are extensively used. Use temperature vary: -50 to 150 °C

Gözden geçirmek

0 people rated this product

The Kooples

CS3mm EPDM O RING ID 4/4.1/13/14.5/20/21/22.15/24.5/28*3mm100PCS O-Ring Gasket Seal Exhaust Mount Rubber Insulator Grommet ORING

Free shipping & returns

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection