Beschreibungen

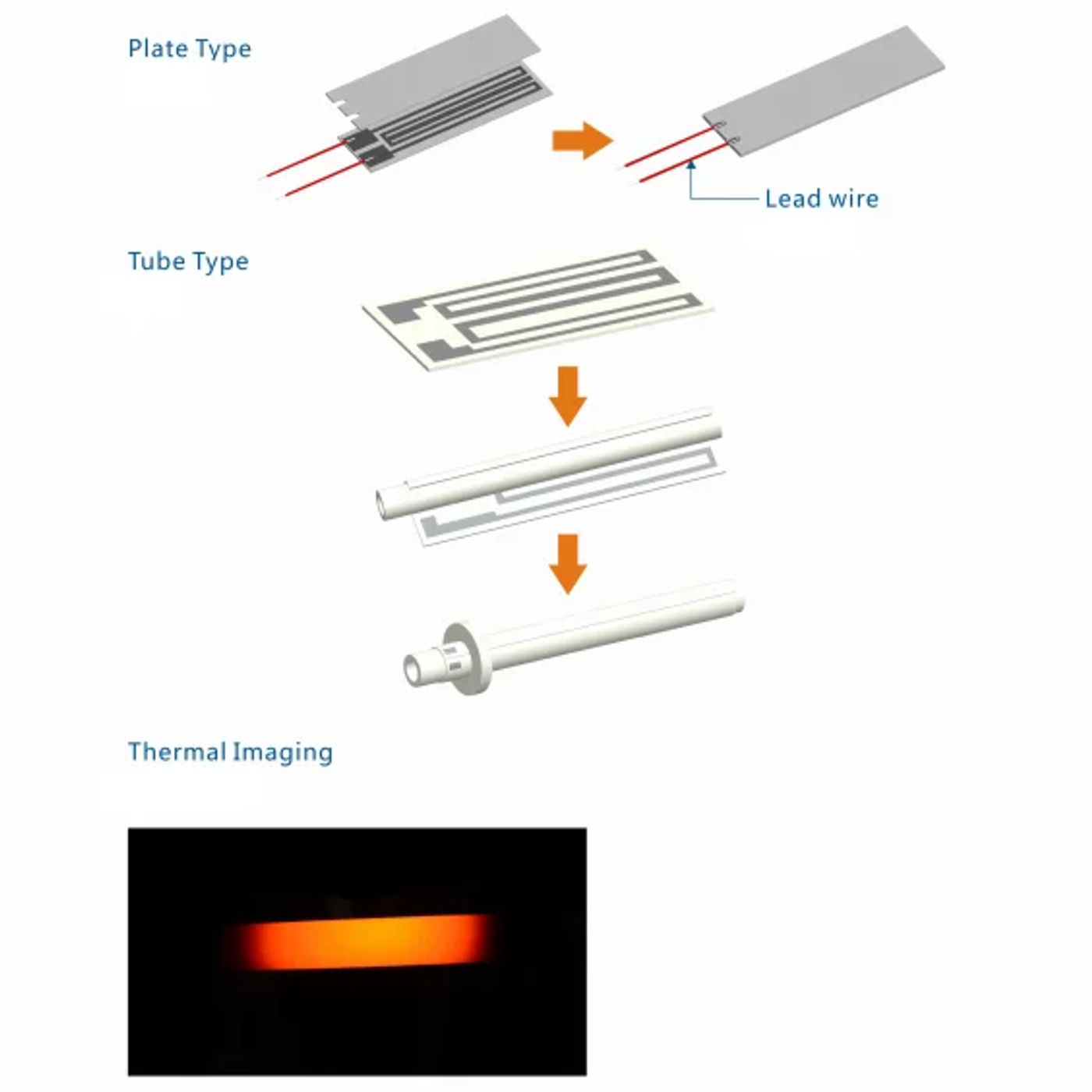

Quick Heating Plate MCH Heat Element Alumina Ceramic Disc Heaters Dia11 IntroductionQuick Heating Plate MCH Heat Element Alumina Ceramic Disc Heaters Dia11 is produced via implementing exotic ceramic lamination processes. MCH prints resistors on alumina sheet, and it&;s laminated and sintered for one piece ceramic warmers can function in atmospheric and vacuum environment. MCH technology affords meaningful advantages over metal normal sheath heaters,while the latter has boundaries in thermal performance and material compatibility with PTC, MCH is extra energy saving, more secure and higher efficient. Currently, MCH is widely used as revolutionary heater in machinery, medical, semiconductor, digital electric industries,etc. Features of Quick Heating Plate MCH Heat Element Alumina Ceramic Disc Heaters Dia111. Compact, light weight and energy-saving:High calories watt density; Good thermal efficiency. 2. Superior thermal properties: Rapid warmth increase;Uniform temp distribution available; High levels of insulation contact with water. 3. High reliability: Superior dielectric strength and electric insulation properties; Superior antioxidant design; Superior chemical resistance. four electrical noise 5. Environmental Technical InfoBeing built into the base ceramic of alumina and laminated and sintering into one piece, is secure and insulated from the exterior air. Other ProductALN Aluminum Nitride Ceramic Heater Zirconia Ceramic Heater Porous Ceramic Heater Alumina Ceramic Heater Company InfoZhuhai MW Technology Co., Ltd. become based in 2017. As an modern developer and manufacturer of MCH ceramic heating facets and printed circuits utilizing IC technology, MW owns its RD department, clean room, progressed printing equipment, furnace and patent-protected inventions. MW adheres to technological innovation and has been focusing on the construction and manufacturing of digital ceramics and related ceramic components. The recent production of MCH electrical ceramic heating facets with plate-shaped, special-shaped, rod-shaped and different shapes are broadly used because the major heating ingredients in large and small kin appliances akin to air conditioners, fan heaters, and hair straighteners, etc. At present, we've five kiln manufacturing traces and the month-to-month manufacturing capability is set 500,000pcs. Through the honest cooperation of our team, the advantages have elevated tremendously ago two years, and the product wonderful has been nicely acquired by means of nearly all of customers. Looking to the future, we’ll proceed to adhere to the leadership philosophy of "people-oriented, progressive development" , the carrier aim of "customer first, repute first" , and the development goal of "achievements of enterprises, talent training, carrier society" . We’ll take the marketplace because the guide, take the science and expertise development as the theme, take the excellence to be the 1st because the opportunity, and commit to the construction and introduction of domestic progressed manufacturing know-how to serve the house and abroad markets, to ensure the product quality, technical level, provider point within the home industry to maintain a leading position. Package ShipmentQuick Heating Plate MCH Heat Element Alumina Ceramic Disc Heaters Dia11 would be packed effectively before cargo to forestall damage. We assuredly deliver our MCH ceramic heating components through DHL. But we could replace the cargo in keeping with your need. Tips1. Should eavesdrop on the outside of ceramic heater to circumvent stained with oil, dirty akin to the water resistant when installation, which to bypass ceramic heater injury because of its poor warm temperature dissipation. 2. The working environment of ceramic heater is opposed to the legislation immoderate warmth and cold, which to forestall bloodless and scorching surprise damage. 3. The working voltage of ceramic heater should be controlled within the fluctuate of the rated voltage in an effort to quit the ceramic heater from load and impact the service life. 4. Ceramic heater when heating within the water or liquid. It needs to be forbidden to add water after dry suddenly, all of the heating pats within the container should be completely submerged within the water, the water point should over the heat element, otherwise it’ll trigger heating detail fracture and damage. 5. Ceramic heater must be perpendicular to the cavity when installation, in some other case the skin temp will not uniformity and make the bubbles that will make the part heat and make the heater broke 6. When ceramic heater is working, strength on after watering to stop dry heat. FAQ1. Can the product be customized? Yes OEM and ODM are available. 2. Do you assist sample order? Most of up to date items stock are available. Customized support. 3. What&;s your after sales? We will music the product logistics till you get the product. When you get hold of the goods, please examine the product and give us suggestions we are ready to provide options in line with your feedback. Please touch for more details GU Zhuhai MW Technology Co.,Ltd. Tel: +86 0756 3689220Fax: +86 0756 3689309Email: cara@mwheater/ WhatsApp: +86 15819038781WeChat: UtopiaGYSkype: live:

Rückmeldung

0 people rated this product

Cotelac

Quick Heating Plate MCH Heat Element Alumina Ceramic Disc Heaters Dia11

Free shipping & returns

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection