Beschreibungen

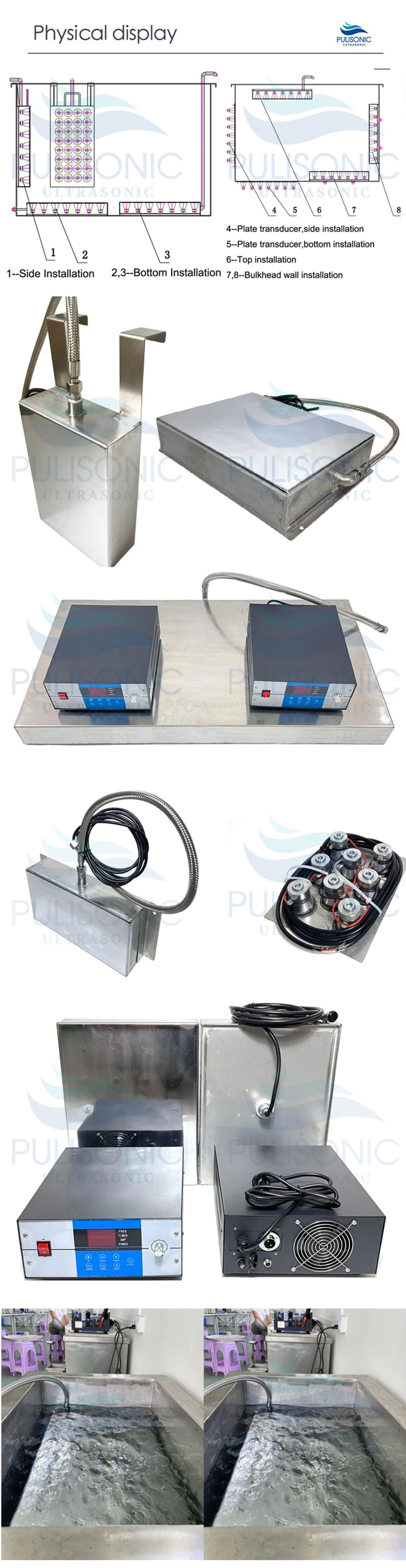

28Khz 2000W Power And Time Adjustable Industrial Ultrasonic Cleaning Transducer Vibarting PackProduct introduction:The Ultrasonic Immersible Transducer Packis often known as an ultrasonic vibration area or an ultrasonic cleansing box, and is an ultrasonic cleaning components which is shaped via bonding an ultrasonic vibrator to a stainless steel case and an ultrasonic generator. It is generally positioned in numerous cleaning tanks for ultrasonic cleaning purposes. The length of the vibration plate and the path of the lead tube would be made into the lowest vibration type, the component vibration variety and the tip vibration kind in line with the set up position, and the affect of thorough cleansing would be completed by using diverse requirements. Suitable for electronic parts, electroplating hardware, auto parts, optical lenses, jewelry, glassware, filter out cores, spinnerets, clinical equipment, etc. Principle:The operating principle of the ultrasonic vibrating plate discipline is that the ultrasonic generator generates super-audio electric energy elevated than 20KHZ, and the transducer is converted into the same frequency mechanical vibration into the cleansing liquid, and the ultrasonic conduction is ahead and forward, which generates countless tiny bubbles. These bubbles are customary and grown in the unfavorable stress field by which the ultrasonic waves propagate longitudinally, and rapidly rupture within the superb pressure region. The formation, growth, and speedy rupture of such tiny bubbles are referred to as "cavitation effects." In the cavitation effect, the immediate high pressure of more than 10,000 atmospheres is generated after the bubble bursts, and the immediate immoderate stress continually generated is like a sequence of small explosions consistently bombarding the exterior of the object, so that the outside of the thing quickly falls off. Performance characteristics:1) Ultrasonic vibration plate area with high quality high-performance transducer and ultrasonic generator, solid cleaning energy and stable performance) The vibration discipline can be assembled into any water tank or container as an ultrasonic cleansing machine, saving kit costs) Ultrasonic vibration plate subject is mostly manufactured from entirely imported 2mm stainless-steel plate with precision welding, acid and alkali resistance, and durable) Flexible and useful to use to various cleansing requirements, the vibration plate area would be organized on the bottom surface, component surface or height surface of the cleansing tank as needed) Ultrasonic vibration plate area and ultrasonic era supply and vibration box are designed separately, which is easy to maintain and maintain) Ultrasonic vibrating plate area has a wide range of applications. In addition to cleaning, it can be put into assorted functions comparable to homogenization and environmental water treatment. Application scope of ultrasonic vibration plate:1. Machinery industry: cutting off of anti-rust grease; cleansing of measuring tools; degreasing and derusting of mechanical parts; cleaning of engines, carburetors and auto parts; dredging and cleansing of filters and screens, etc. Especially in the railway industry, it is very correct for the degreasing and decontamination of the air conditioner of the train, and the derusting, degreasing and anti-rusting of the several ingredients of the practice head. Surface remedy industry: degreasing and rust removal before electroplating; cleansing before ion plating; phosphating treatment; cutting off carbon deposits; cutting off oxide scale; cutting off sprucing paste; floor activation treatment of metallic workpieces, etc. Instrumentation industry: immoderate cleanliness of precision parts, cleaning earlier than assembly, etc. Electronic industry: Removal of rosin and solder spots on printed circuit boards; cleansing of mechanical and digital aspects comparable to excessive voltage contacts. Medical industry: cleaning, disinfection, sterilization of clinical equipment, cleaning of examine utensils, etc. Semiconductor industry: excessive cleanliness cleansing of semiconductor wafers. Watch and jewellery industry: get rid of sludge, dust, oxide layer, sprucing paste, etc. Chemical and biological industries: cleansing and descaling of laboratory utensils, etc. Optical industry: degreasing, sweating and dirt cutting off of optical devices. Textile printing and dyeing industry: cleaning textile spindles, spinnerets, etc. Petrochemical industry: cleansing and dredging of metallic clear out screens, cleansing of chemical containers, exchangers, etc. Others: liquid defoaming (removing dissolved air) in photosensitive material manufacturing, papermaking, and certain food fields(mm)Frequency (Khz)Power(W)Ultrasonic TransducerPLS-ZBH300W300*190*10025,28,33,40,80,1303006PLS-ZBH600W360*275*10025,28,33,40,80,13060012PLS-ZBH1000W450*350*10025,28,33,40,80,130100020PLS-ZBH1200W470*380*10025,28,33,40,80,130120024PLS-ZBH1500W520*450*10025,28,33,40,80,130150030PLS-ZBH1800W560*450*10025,28,33,40,80,130180036PLS-ZBH2000W650*450*10025,28,33,40,80,130200040PLS-ZBH2400W740*520*10025,28,33,40,80,130240048PLS-ZBH3000W820*540*10025,28,33,40,80,130300060PLS-ZBH5000W1200*590*10025,28,33,40,80,1305000100Above are unmarried frequency ultrasonic immersible transducer pack OEM Ultrasonic Immersible Transducer Pack(Size, Frequency,Power)

Rückmeldung

0 people rated this product

Salomon

28Khz 2000W Power And Time Adjustable Industrial Ultrasonic Cleaning Transducer Vibarting Pack

Free shipping & returns

QWQER Express,

QWQER Express, USPS,

USPS, DHL

DHL

Shopping security

- Safe payment options

- Secure privacy

- Secure logistics

- Purchase protection